Compact CNC Plasma Cutting

Plasma cutting is a cutting process in which a gas is conveyed to a nozzle from which it is ejected at high pressure. In this phase, an electric arc is created through the gas between an electrode and the surface of the metal to be cut, which transforms the gas into plasma. The plasma transfers heat to the metal material until it reaches melting temperature, creating a cutting point in the metal structure. The kinetic energy of the gas itself ejects the molten metal as the torch proceeds to create a cutting line on the metal body.

Plasma cutting can cut almost any metal, including steel, stainless steel, aluminum, titanium, copper and brass.

Manual plasma cutting machines are available on the market, whose cutting quality is closely related to the skill of the operator. However even the most skilled hand, is limited in complex shapes and is unable to reproduce two equal pieces. Otherwise, an operation performed by a digital control (CNC) allows to perform precise, repeatable movements and create complicated shapes.

(Watch the video )

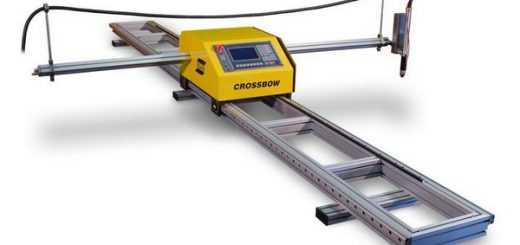

CrossFire is a system that integrates plasma cutting with numerically controlled electromechanical handling. It is a competitive CNC plasma cutting that makes this technology affordable even for small businesses and fans of DIY.

Thanks to the CNC cutting system it is possible to obtain cuts of the most disparate shapes in a fast and precise way, otherwise impossible with normal cutting tools.

Crossfire integrates perfectly with common CAD design software, with which to create new projects, but it is also possible to take advantage of the drawings of the library available online on the Langmuir System website.

With CrossFire it is possible to carry out work in your garage that normally could only done by professional activities. Unlike traditional machining methods (material removal), CNC plasma cutting does not require complicated fixings and configurations: just set the torch height and run the program.

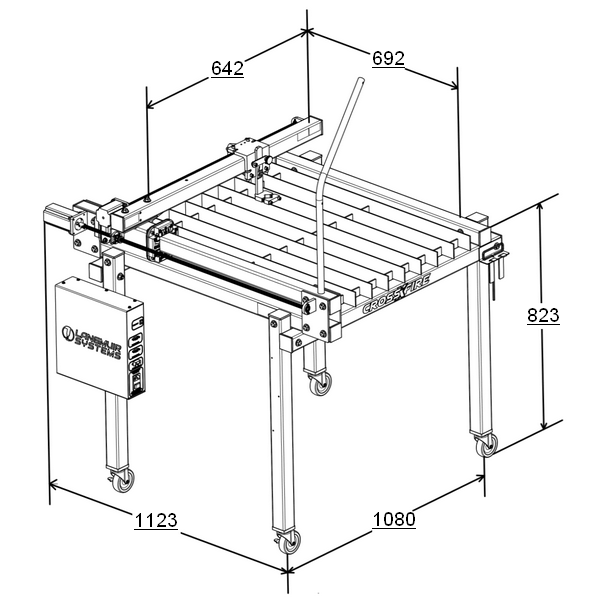

Once machining is complete, the cutting table can be folded to reduce the size when plasma cutting is not in use.

SPECIFICATIONS

- Cutting Area : 642mm (X) x 592mm (Y) x 76mm (Z)

- Weight : 50 kg

- PC interface : USB

- Cutting speed : 127 mm / s

- Power supply : 110/220 V

For more information, visit the website .