Laser Cleaning

Surface cleaning is a more or less tiring operation obtainable through mechanical processes, with the use of brushes, abrasive papers, or by using sandblasting or the action of specific chemical products.

P-Laser develops and produces laser equipment for cleaning surfaces, as an alternative to traditional tools for removing rust, dust, oxides, oil and other contamination from metal, plastic, ceramic, glass, stone or concrete.

This laser cleaning technique leaves the original substrate intact, thus offering unexpected possibilities for a variety of industrial surface preparation and cleaning applications.

The number of applications of laser systems is constantly increasing, new possibilities are discovered and explored every day: from rust removal to the restoration of natural stone building facades. Paint removal, discoloration, mould cleaning, oil removal, special surface treatment even labeling and marking.

The industrial applications for which P-Laser products are used, range from the smallest inaccessible area to large surfaces of public or private infrastructures.

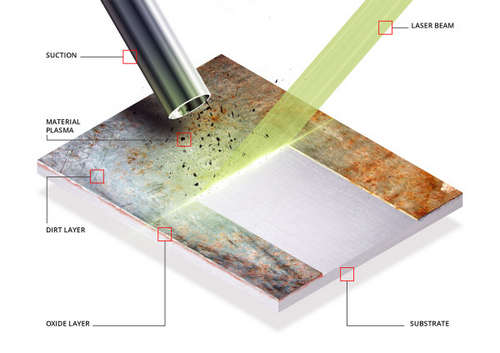

Industrial laser cleaning, or ablation, is the process of removing unwanted material from a solid surface by irradiating it with a laser beam. By absorbing the energy of the laser beam, the target material is heated very quickly, causing it to evaporate or sublimate, while the underlying surface, not absorbing energy, remains intact.

(Watch the video )

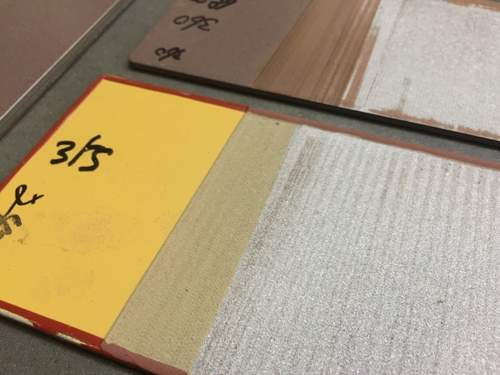

By manipulating the laser flux, its wavelength and its pulse length, the amount of material that is removed by a single laser pulse can be controlled with extreme precision. For this reason, laser cleaning is suitable for rapid removal of deep rust or for removing a thin layer of paint, without damaging the base.

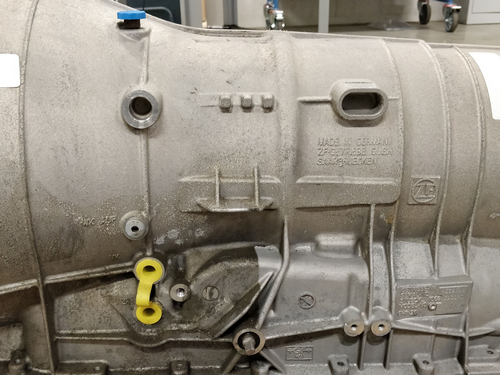

Laser cleaning systems have a great ability to remove rust or de-oxidize objects of the most disparate shapes, even reaching the points less reachable by traditional systems.

These machines are suitable in the removal of paint before welding, brazing, gluing or new painting processes.

These lasers are also capable of removing paint layer by layer, if you don’t want to remove all at once.

Important practical benefits also derive from its use for the elimination of greasy or oily substances, dirt or other contaminants. A practical example could be the end of a production line as a final cleaning of the product before delivery to the customer.

In the restoration process, laser cleaning was used with satisfactory results, for example in the preservation of the stone. It is able to remove encrustations, returning appreciable results from an aesthetic point of view without producing negative effects.

The diameter of the laser beam can be adjusted so that it can treat areas of different sizes, there is no physical contact between the object to be cleaned and the laser equipment, which is relevant in the treatment of fragile materials, also does not require use of chemicals or abrasive products.

P-Laser develops and manufactures the most advanced industrial laser equipment in the world for manual and automated use (patent pending). These laser cleaning systems range from 20 to 1000 watts of extremely precise laser light, and also offer unexpected possibilities for an ever-increasing number of industrial applications, ranging from marking or labelling to surface preparation for non-destructive testing.

For more information, visit the website .