3D Printer for Construction

BOD2 is a second generation robotic 3D printer for building construction, made by COBOD with the idea of full automation in the construction industry.

BOD 2 is based on the experience obtained with the first BOD version printer, of which it incorporates functionality and stability but improved compared to the first project. It is therefore a system that has already been tested and proven.

The system is based on the well-known concept of 3D printers, that is the deposition in layers of low-consistency filler material which solidifying allows the deposition of the next layer until the construction is completed. The difference in this case is represented by the filler material or cement mortars mixed with aggregating elements, also recycled.

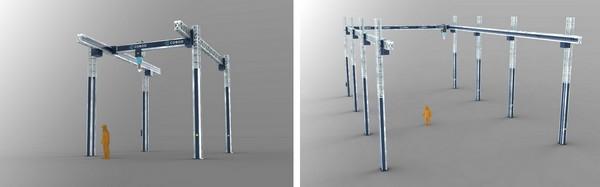

This printer is designed for a modular system , so it can be adapted to any project. From time to time, it is a matter of deciding the size of BOD2: according to the specifications of the project, new modules are added.

The modules are made with the gantry system which is optimal for on-site projects as well as for the fabrication of off-site elements.

BOD2 is 3 times faster than the first generation, with a printing speed of 18 meters / minute, 50 square meters buildings can be built in one day.

(Watch the video )

Printing time is influenced by the hardening of the concrete mix which strongly depends on the weather conditions and the design of the mixture. The time required to allow the next layer to be laid can be set among the software parameters, based on the current laying conditions.

Interchangeable nozzles are optimized and developed to ensure smooth surfaces, the standard layer height is 2 cm and the width 5 cm.

In addition to the modular system, the BOD2 is flexible in terms of assembly, it can be mounted on the foundation or on mobile concrete pillars. An experienced team can set up the printer in less than 4 hours also depends on the quantity of modules.

A great advantage of robotic 3D printing of buildings is the possibility of creating free shapes: the printer doesn’t care if the walls are straight or curved.

The speed of laying of the material and the low labour requirements mean that the cost of a 3D printed building is relatively low compared to buildings constructed with traditional methods.

With the BOD2 it is possible to create inclinations or overhangs (non-vertical walls). The possible degree of inclination depends on the material properties and geometry. For very stable geometries, COBOD was able to print overhangs up to 30 degrees (measured from vertical walls).

The openings for windows and doors are printed directly from the drawing. The printer code must be adjusted (with the software) so that the printing is stopped to allow time to position the lintels on which subsequent layers of concrete mix will be deposited. After printing, you can place the type of windows and doors you want.

The maximum dimensions of the printer are 15 meters wide, 10 meters high for an unlimited length.

For more information, visit the website.